Wednesday, November 12, 2014

12V Speed Dimmer Controller Diagram Circuit

SILICON CHIP has produced a number of DC speed controllers over the years, the most recent being our high-power 24V 40A design featured in the March & April 2008 issues. Another very popular design is our 12V/24V 20A design featured in the June 1997 issue and we have also featured a number of reversible 12V designs.Circuit looks like:

For many applications though, most of these designs are over-kill and a much simpler circuit will suffice. Which is why we are presenting this basic design which uses a 7555 timer IC, a Mosfet and not much else. Being a simple design, it does not monitor motor back-EMF to provide improved speed regulation and nor does it have any fancy overload protection apart from a fuse. However, it is a very efficient circuit and the kit cost is quite low.Parts layout:

There are many applications for this circuit which will all be based on 12V motors, fans or lamps. You can use it in cars, boats, and recreational vehicles, in model boats and model railways and so on. Want to control a 12V fan in a car, caravan or computer? This circuit will do it for you.Circuit diagram:

The circuit uses a 7555 timer (IC1) to generate variable width pulses at about 210Hz. This drives Mosfet Q3 (via transistors Q1 & Q2) to control the speed of a motor or to dim an incandescent lamp.Halogen lamps:While the circuit can dim 12V halogen lamps, we should point out that dimming halogen lamps is very wasteful. In situations where you need dimmable 12V lamps, you will be much better off substituting 12V LED lamps which are now readily available in standard bayonet, miniature Edison screw (MES) and MR16 halogen bases. Not only are these LED replacement lamps much more efficient than halogen lamps, they do not get anywhere near as hot and will also last a great deal longer.

Source: Silicon Chip 15 November 2008

Mini Subwoofer 5″ – 6″ BandPass 4th Order Isobaric

The order of 4 or sealed rear chamber bandpass system is essentially a system of watertight enclosures with the addition of an acoustic filter for the driver. The resulting system usually provides a lower cut-off frequency, the compromise that a larger case. The space can be reduced by two drivers in isobaric configuration.

4th-order bandpass systems generally show better able to handle the functions that the other major systems are considered. The transient response and is second only to the sealed enclosure systems, making it a good choice for subwoofer applications.

Since all output 4th order bandpass system is via the port, the largest diameter possible for the port area should be used to minimize noise from the port. The ports must be incinerated where possible, for the same reasons.

The 4th order bandpass system rarely allows a perfect bandpass response - there is usually an out-of-band noise present in the production. A notch filter can be used simply to reduce the noise as audible. Otherwise, a lowpass filter used in series with the driver, but the in-band response system may be affected if this approach is taken.

As the speaker sound 4th order band pass issued by the openings or ports on the port side of the box, the port noise inevitable.

This unwanted noise can be minimized by a notch filter and the largest diameter possible for the port of the area should definitely be used. Another option is to burn the ports of the 4th order bandpass room as this will certainly help to reduce unwanted extra from the subwoofer.

Mini SubWoofer Power Amplifier clik for detail

WOOFER / MID MODEL - 5MP60 / N

Specifications

Nominal Basket Diameter 5 "/ 125mm

Impedance 8 ohm

RMS Power 50 Watts

Program Power 100 Watts

Frequency response 50Hz - 12.0kHz

Sensitivity (1W/1m) 91dB

Voice Coil Diameter 1 "/ 25.8mm

BL Factor 6.4 N / A

Voice Coil Length 14 mm

Air Gap Height 6mm

X Damage (peak to peak) 20 mm

Magnetic Assembly Weight 2.2 lbs / 1.0 kg.

Edit Information

Diameter 5.28 "/ 134mm x 5.28" / 134mm

Bolt Circle Diameter 5.4 "/ 137mm

Baffle Cutout Diameter --

- Front Mount 4.72 "/ 120mm

Many of the 4 mounting holes

Volume displaced by driver, 019 m 3 / .5 liter

Total Depth 2.68 "/ 68mm

Net weight 2.64 lbs / 1.2 kg.

Weight 2.8 lbs / 1.27 kg.

Materials

Basketball aluminum diecast

Polypropylene cone

Rubber Surround

Voice Coil Wire Copper

Ferrite

Thiele-Small Parameters

Resonance Frequency (FS) 60 Hz

Impedance (Re) 5.33 ohms

Coil Inductance (Le) 0.4 mH

Mechanical Q (Qms) 1.604

Electrical Factor (Qes) .35

Total Q (Qts) .29

Comp. Equivalent Vol. (Vas) 35 FT3 / 9.8 Liter

Voice Coil Overhang (Xmax) 4.0mm

Reference yield 5%

Volume Displacement 34 cm3

Rc servo controller circuit using PIC18F252

Rc servo controller circuit using PIC18F252

rc servo controller circuit

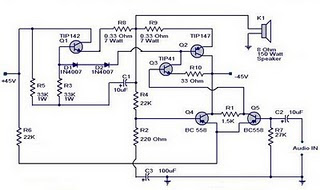

25 Watt Audio Amplifier Circuit

Circuit diagram:

Parts:R1 = 47K

R2 = 4K7

R3 = 1K5

R4 = 47K

R5 = 390R

R6 = 470R

R7 = 33K

R8 = 150K

R9 = 15K

R10 = 27R

R11 = 500R-1/2W

R12 = 10R

R13 = 10R

R14 = 220R

R15 = 220R

R16 = 10R

R17 = 8.2R-2W

R18 = 22R-4W(wirewound)

C1 = 470nF-63V

C2 = 330pF-63V

C3 = 470µF-63V

C4 = 100nF-63V

C5 = 470µF-63V

C6 = 100nF-63V

C7 = 100µF-25V

C8 = 100nF-63V

C9 = 10pF-63V

C10 = 1µF-63V

C11 = 100nF-63V

Q1 = BC560C

Q2 = BC560C

Q3 = BC560C

Q4 = BC560C

Q5 = BC560C

Q6 = BD140

Q7 = BD139

Q8 = IRF530

Q9 = IRF9530

Power supply section:

Power supply circuit diagram:

Parts:R1 = 3K3-1/2W

C1 = 10nF-1000V

C2 = 4700µF-50V

C3 = 4700µF-50V

C4 = 100nF-63V

C5 = 100nF-63V

D1 = 200V 8A Diode bridge

D2 = 5mm. Red LED

F2 = 3.15A Fuses with sockets

F2 = 3.15A Fuses with sockets

T1 = 220V Primary, 25 + 25V Secondary 120VA Mains transformer

PL1 = Male Mains plug

SW1 = SPST Mains switch

Notes:

- Can be directly connected to CD players, tuners and tape recorders. Simply add a 10K Log potentiometer (dual gang for stereo) and a switch to cope with the various sources you need.

- Q6 & Q7 must have a small U-shaped heatsink.

- Q8 & Q9 must be mounted on heatsink.

- Adjust R11 to set quiescent current at 100mA (best measured with an Avo-meter connected in series to Q8 Drain) with no input signal.

- A correct grounding is very important to eliminate hum and ground loops. Connect to the same point the ground sides of R1, R4, R9, C3 to C8. Connect C11 to output ground. Then connect separately the input and output grounds to power supply ground.

- An earlier prototype of this amplifier was recently inspected and tested again after 15 years of use. Results, comments and pictures are shown here.

Tuesday, November 11, 2014

Simple Solar Tracking System

Fig. 1: Circuit of solar tracking system |

Fig. 1 shows the circuit of the solar tracking system. The solar tracker comprises comparator IC LM339, H-bridge motor driver IC L293D (IC2) and a few discrete components. Light-dependent resistors LDR1 through LDR4 are used as sensors to detect the panel’s position relative to the sun. These provide the signal to motor driver IC2 to move the solar panel in the sun’s direction. LDR1 and LDR2 are fixed at the edges of the solar panel along the X axis, and connected to comparators A1 and A2, respectively. Presets VR1 and VR2 are set to get low comparator output at pins 2 and 1 of comparators A1 and A2, respectively, so as to stop motor M1 when the sun’s rays are perpendicular to the solar panel.

When LDR2 receives more light than LDR1, it offers lower resistance than LDR1, providing a high input to comparators A1 and A2 at pins 4 and 7, respectively. As a result, output pin 1 of comparator A2 goes high to rotate motor M1 in one direction (say, anti-clockwise) and turn the solar panel.

When LDR1 receives more light than LDR2, it offers lower resistance than LDR2, giving a low input to comparators A1 and A2 at pins 4 and 7, respectively. As the voltage at pin 5 of comparator A1 is now higher than the voltage at its pin 4, its output pin 2 goes high. As a result, motor M1 rotates in the opposite direction (say, clock-wise) and the solar panel turns.

Fig. 2 Proposed assembly for the solar tracking system |

Mobile Car Stereo Player

Sunday, November 9, 2014

Automatic Low Power Emergancy Light

In the charger power supply section, an input AC main is stepped down by T1 to deliver 9V, 500mA to the bridge rectifier, which comprises diodes D1 through D4. Filter capacitor C1 eliminates ripples. Unregulated DC voltage is fed to input pin 3 of IC1 and provides charging current through D5 and limiting resistor R15. By adjusting preset P1, the output voltage can be adjusted to deliver the required charging current. When the battery gets charged to 6.8V, D6 conducts and charging current from IC1 finds a path throughQT1 to ground and it stops charging of the battery. When mains power is available, the base of Q2 remains high and Q2 does not conduct. Thus LEDs are off.

On the other hand, when mains fails, the base of Q2 becomes low and it conducts. This makes all the LEDs glow. The mains power supply, when available, charges the battery and keeps the LEDs off as Q2 remains cut-off. During mains failure, the charging section stops working and the B1 supply makes the LEDs glow. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for battery and switches. We have tested the circuit with twelve 10mm white LEDs. You can use more LEDs provided the total current consumption does not exceed 1.5A. Driver transistor Q2 can deliver up to 1.5A with proper heat-sink arrangement.

Circuit diagram:

P1 = 2.2K

R1-R12 = 100R-1/2W

R13 = 1K-1/2W

R14 = 180R-1/2W

R15 = 16R/5W

R16 = 1.2K

C1 = 1000uF-25V

D1-D5 = 1N4007

D6 = 6.8V-0.5W Zener

D7-D18 = 10mm- White LEDs

Q1 = BC548

Q2 = BD140

B1 = 6V-4.5Ah Battery

IC1 = LM317

T1 = 9Vac-Transformer

LED Volt Meter Circuit

Saturday, November 8, 2014

Ampere or Current Booster Circuit

Current up to 1500mA(1.5amp) will flow through the regulator, anything above that makes the regulator conduct and adding the extra needed current to the output load. It is no problem stacking power transistors for even more current. (see diagram). Both regulator and power transistor must be mounted on an adequate heatsink.

Circuit diagram:

As the amplifier circuit also uses a number of frequencies to drive the loudspeaker, the bass frequencies will be reduced. Therefore need to be plugged the bass-boost control at fedback loop amplifier, this is done to overcome the decline in quality.

As the amplifier circuit also uses a number of frequencies to drive the loudspeaker, the bass frequencies will be reduced. Therefore need to be plugged the bass-boost control at fedback loop amplifier, this is done to overcome the decline in quality.